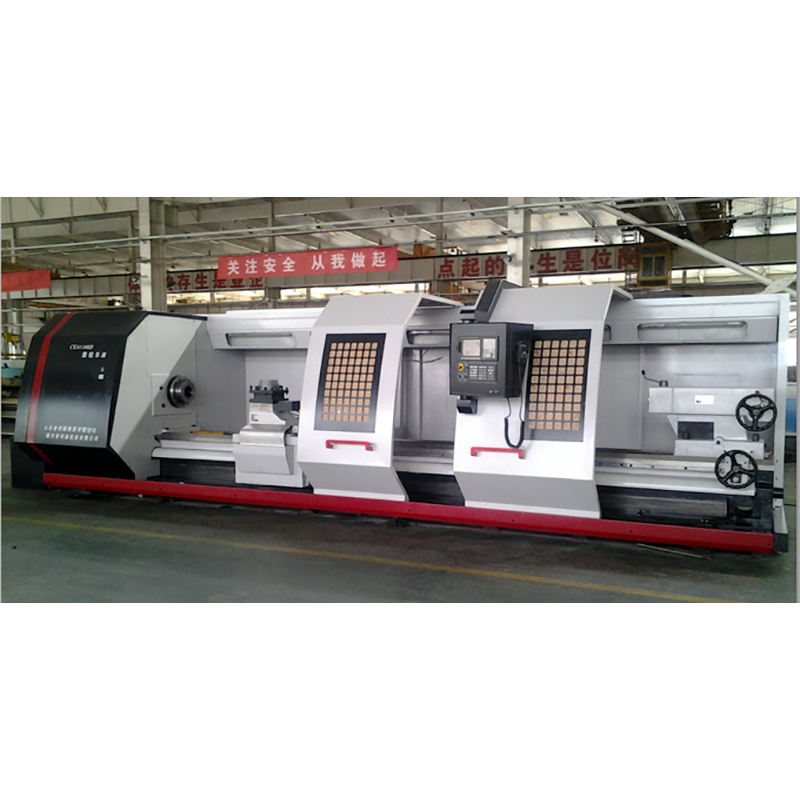

I-CH61200L CNC iziko lokujika eline-C axis

Umyalelo omfutshane

Lo matshini udibene ne-C axis, ukondla i-X kunye ne-Z axis, i-axis emithathu inokudityaniswa kwaye ihambe kunye nemisebenzi emininzi kunye nokusebenza kakuhle kokusika.

Idibene ne-SIEMENS 828D CNC inkqubo.

Iigiya ezimbini zesantya sokusonta, kunye nesantya esinganyatheliyo ngaphakathi kweegiya, ukutshintsha kwegiya yehydraulic, ukusika umgca wesantya esingaguqukiyo.Injini ephambili yokusonta yi-SIEMENS 37KW AC servo motor, yehlisa isantya kunye nokunyusa i-torque ngegiya, isantya se-spindle yi-5-200rpm.

I-axis ye-C ilayishwe ngokuchaneka okuphezulu kwe-AC servo motor, kunye nokutshixa okuzenzekelayo kwe-hydraulic, kunye nokusetyenziswa kwegrayithi esetyhula ukufumanisa indawo yokwenene;I-X axis ithatha i-SIEMENS AC servo motor eqhutywa kunye nokuchaneka okuphezulu kwebhola ye-screw pair ukuqonda intshukumo esecaleni, i-Z axis ithatha i-SIEMENS AC servo motor drive high precision worm reducer ukuze ihambe ixesha elide, zombini i-X, i-axis ye-Z ixhotyiswe ngegrayiti yokubhaqa indawo yokwenyani, ulawulo lwelophu evaliweyo, ngokuchaneka kokuma okuhle kunye nokuphinda ukuchaneka kokubeka

ukusetyenziswa komatshini

Lo ngumatshini wokusika osebenzayo, ofanelekileyo ukusika isinyithi, isinyithi kunye ne-non-ferrous metal processing with high-speed steel and hard alloy tool.Inokuba kukujika isangqa sangaphandle, isiphelo sobuso, ukusika igroove, ukusika, ukusika umngxuma wangaphakathi, isitshixo sokugaya, i-spiral groove, ukubhola kunye nokucofa.

Sketch imephu yomsebenzi:

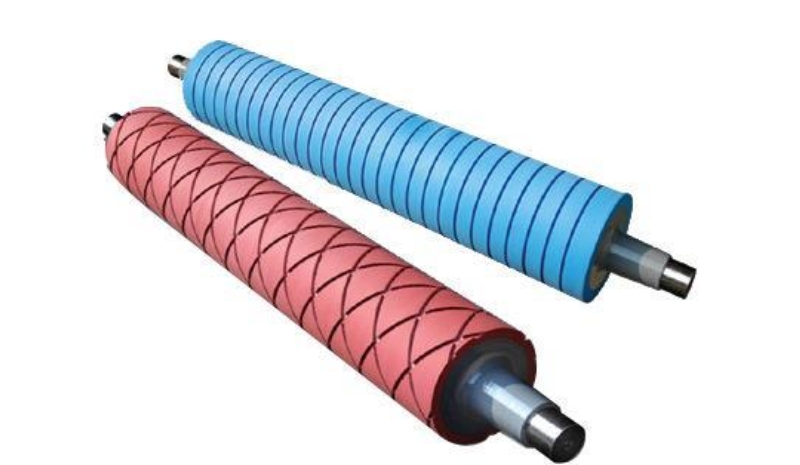

Isitshixo sokugaya

Intambo yokugaya enokutshintsha kwepitch

I-Milling spiral groove, ipateni yesikali

ipharamitha kunye nomthamo

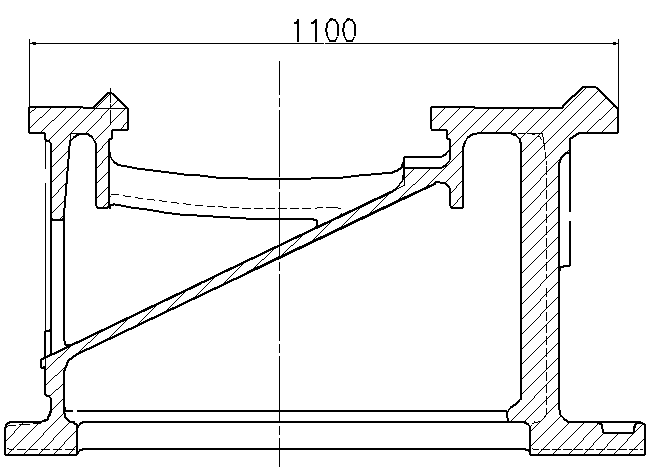

| Ububanzi bendlela yesikhokelo | 1100mm |

| Max.jiwuzisa idiameter phezu kwebhedi | φ2040mm |

| Max.jiwuzisa idayamitha phezu kwepali yesixhobo | φ1500mm |

| Max.ubude bomsebenzi | 12000mm |

| Max.workpiece ubunzima phakathi iziko | 10T |

| usulelo oluphambili | |

| Ukuthwala kwangaphambili kwe-spindle | φ220mm |

| Uluhlu lwesantya sombhobho | 5-200r / min |

| I-Spindle bore diameter | φ130mm |

| I-taper yangaphambili yomngxuma wokusonta | i-metric No.140 |

| Amandla emoto aphambili, i-servo motor | 37KW |

| Spec.yesiphelo sokusonta | 1:30 |

| ukuhanjiswa kwesondlo | |

| X ukuhamba kwe-axis | 85mm |

| z uhambo oluhamba nge-axis | 11800mm |

| x isantya sohambo olukhawulezayo | 4m/min |

| z isantya sohambo olukhawulezayo | 4m/min |

| I-Servo motor torque od x i-axis | 27Nm |

| Servo motor torque od z axis | 36Nm |

| Horizontal 8 isikhundla amandla turret | 0.5.473.532.8 |

| Ubungakanani becandelo le-shank yesixhobo | 32mmx32mm |

| I-Tailstock | |

| I-Quill diameter ye-tailstock | φ260mm |

| Ukuhamba ngeQuil | 300mm |

| Taper umngxuma wequill | i-metric No.80 |

| Umncedisi uphumle (2 iiseti) | |

| Kuvaliwe ukuphumla okuzinzileyo | φ400-φ700mm |

| qha | |

| Imihlathi emine | φ1600mm |

| Umgca weC | |

| Max.itorque phantsi kwemeko ecinezelweyo | 3000Nm |

| Ukubeka ukuchaneka kwe-C axis | 36″ |

| Phinda ukuchaneka kokumisa kwe-C axis | 18″ |

Ulwakhiwo oluphambili

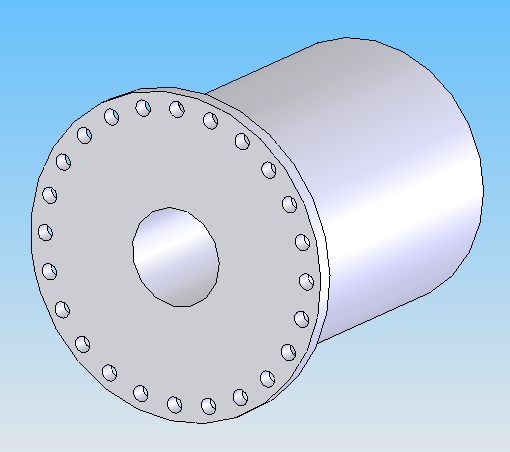

1)ibhedi

Ibhedi luhlobo lomgangatho webhedi kunye nobubanzi be-1100mm kunye ne-resin ephezulu yokuphosa isanti.Izinto eziphathekayo yi-HT300.Ibhedi ineenzuzo zokuqina okuqinileyo, umthamo omkhulu wokuthwala kunye nokuzinza okulungileyo

Indlela yesikhokelo yintaba enye kunye nesakhiwo esinye esithe tyaba, ubulukhuni bendlela yesikhokelo bungaphezulu kwe-HRC52, ubunzulu bokuqina buluncedo ukuba umhlaba.

Umgodlo wangaphakathi womzimba webhedi unikwe i-W shaped ukuqinisa imbambo, eyomeleza kakhulu ukuqina kombhede womatshini kunye nokunciphisa ukuguqulwa ngenxa yokuthwala ubunzima.

Emva kokuguga kwebhedi yokuphosa, kunokususa uxinzelelo olushiyekileyo kwi-casting, kunye nokunciphisa ukukhutshwa koxinzelelo olushiyekileyo ekusebenzeni kunye nokusetyenziswa komatshini.

Kukho imingxunya ethambekileyo negobileyo ngasemva kwebhedi esetyenziselwa ukususwa kwetshiphu.Itshiphu, into epholisayo, ioyile yokuthambisa njalo njalo zisuswa ngqo kwi tray yetshiphu.Ngoko ukucocwa kwe-chip kukulungele, kwaye ulwelo lokupholisa lunokuphinda lusetyenziswe

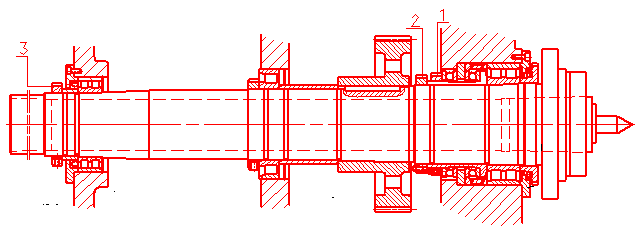

2)Intloko

I-spindle ithatha ukuxhaswa kwamanqaku amathathu, kunye nesiphelo sangaphambili njengesiphelo esisisigxina, umbindi kunye nomva uphela njengesiphelo sokuhamba, isiphelo sangaphambili nasemva njengenkxaso ephambili, kunye nephakathi njengenkxaso yokuncedisa.I-axial positioning ibekwe kwisiphelo sangaphambili se-spindle, ukwenzela ukuba i-spindle ibuyele ngasemva emva kokufudumeza, ikhuphe impembelelo yokwandiswa kwe-thermal ye-spindle ekuchanekeni kwesixhobo somatshini.

Eyona nto iqhuba i-lathe yenziwa yi-Siemens AC spindle motor ngokusebenzisa ibhanti yepuli, igiya kunye nenqanaba eline-hydraulic automatic shift.Uluhlu lwetorque eqhubekayo ye-spindle inkulu kwaye ukusika kwesantya esiguquguqukayo kuya kwenzeka.Ukuthwala i-spindle yintsimbi ekhethekileyo, ngokuchaneka okuphezulu kunye nokuqina okuqinileyo.

I-headstock ifakwe ioli eyomeleleyo, kwaye i-headstock gears kunye neebheringi zithanjiswa ngepompo ekhethekileyo yeoli.Isiphelo sangaphambili se-spindle samkela isakhiwo sokutywinwa kabini kwe-labyrinth kunye ne-slot, enokuthintela ngokufanelekileyo ukuvuza kweoli kunye nezinto zangaphandle ukuba zingene kwi-headstock.

3): iposti yesixhobo

Yamkela i-German SAUTER 8 isikhundla se-horizontal turret 0.5.473.532.8, le turret inomsebenzi wokusika isangqa sangaphandle, isiphelo sobuso kunye nentambo kunye nokugaya, ukubhola kunye nokucofa.Le turret iqhutywa yi-SIEMENS servo motor efakwe kuyo, kwaye idibene nezi zincedisi zilandelayo.

| Iseva.Hayi. | Igama | Uhlobo | Qty |

| 1 | I-turret yamandla | 0.5.473.532.8 | 1 |

| 2 | Intloko yomsiki | 0.5.901.032/077790 | 1 |

| 3 | I-0-degree isibambi sokusika amandla | 0.5.921.106-117859 | 1 |

| 4 | I-90-degree isibambi sokusika amandla | 0.5.921.206-117866 | 1 |

| 5 | Isangqa sangaphandle sokusika isibambi sokusika | B2-60X32X60-113908 | 2 |

| 6 | Isangqa sangaphakathi sokusika isibambi sokusika | E2-60X50-113961 | 2 |

4)Z kunye nomgca ongu-X:

Idayamitha yesikrufu sebhola ye-X i-axis isφ40x5, i-axis engu-Z iqhutywa yi-rack kunye negiya, imodyuli yamazinyo yi-m=5, kunye ne-z axis ithatha ulawulo olupheleleyo lwe-loop ngokugraya ingxelo yerula

5) Isitokhwe somsila

I-Tailstock iquka inxalenye ephezulu kunye nezantsi, i-quill kunye ne-quill center umbutho wokulungelelanisa ulungelelwaniso lufakwe kwindawo ephezulu.Ukuhamba kwe-tailstock kuqhutywa yimoto.Iquill ye tailstock inokujikeleza.

6)inkqubo yokuthambisa

Ukuthanjiswa kweebheringi kwi-headstock, iigiya kunye nokuthwala kwi-headstock kunye nezinye iimeko zibonelelwa yimpompo ekhethekileyo, ukuthambisa iibheringi ze-screw yebhola kunye nendawo nganye yokuthambisa yomatshini ithatha i-lubrication ephakathi kunye ne-concentrative, kunye nexesha lokuthambisa lilungelelaniswe, ukuze ikhusela ngokufanelekileyo ukumosha ioli yokuthambisa, kwaye inokuphucula ngokufanelekileyo impendulo eguquguqukayo yomatshini kunye nobomi benkonzo yendlela yesikhokelo kunye nesijija sebhola.

inkqubo ye-hydraulic

Inkqubo yeHydraulic isetyenziselwa utshintsho oluzenzekelayo lwesantya sokupholisa kunye nokupholisa ngenkani kweegiya kwi-headstock kunye nokutshixa okuzenzekelayo kwe-axis ye-C.

7) Umgca we-C

I-axis ye-C iqhutywa yi-servo motor, inokutshintshela ngokuzenzekelayo kwimowudi yokuhanjiswa kwe-spindle kunye ne-C axis, umva we-spindle ufakwe ngokuchaneka okuphezulu kwe-circular grating ye-C axis kunye ne-brake damping mechanism.Ngenkqubo yokulinganisa i-loop epheleleyo.

Ukuchaneka komatshini

| Gqiba ukusika isangqa sangaphandle | 0.005mm |

| Ukuhambelana komatshini, kubude be-300mm | 0.03mm |

| Ukuthe tyaba kokugqiba ukusika umcaba, | |

| kububanzi obuyi-300mm | 0.025mm, concave |

| Umgca we-X | |

| ukuchaneka kokubeka | X≤0.03mm |

| phinda ukuchaneka kokubeka | X≤0.012mm |

| Umgca weZ | |

| Ukumisa ukuchaneka, kubude be-10000mm | X≤0.13mm |

| Phinda ukuchaneka kwendawo | X≤0.05mm |

| Umgca weC | |

| ukuchaneka kokubeka | 36” |

| phinda ukuchaneka kokubeka | 18” |